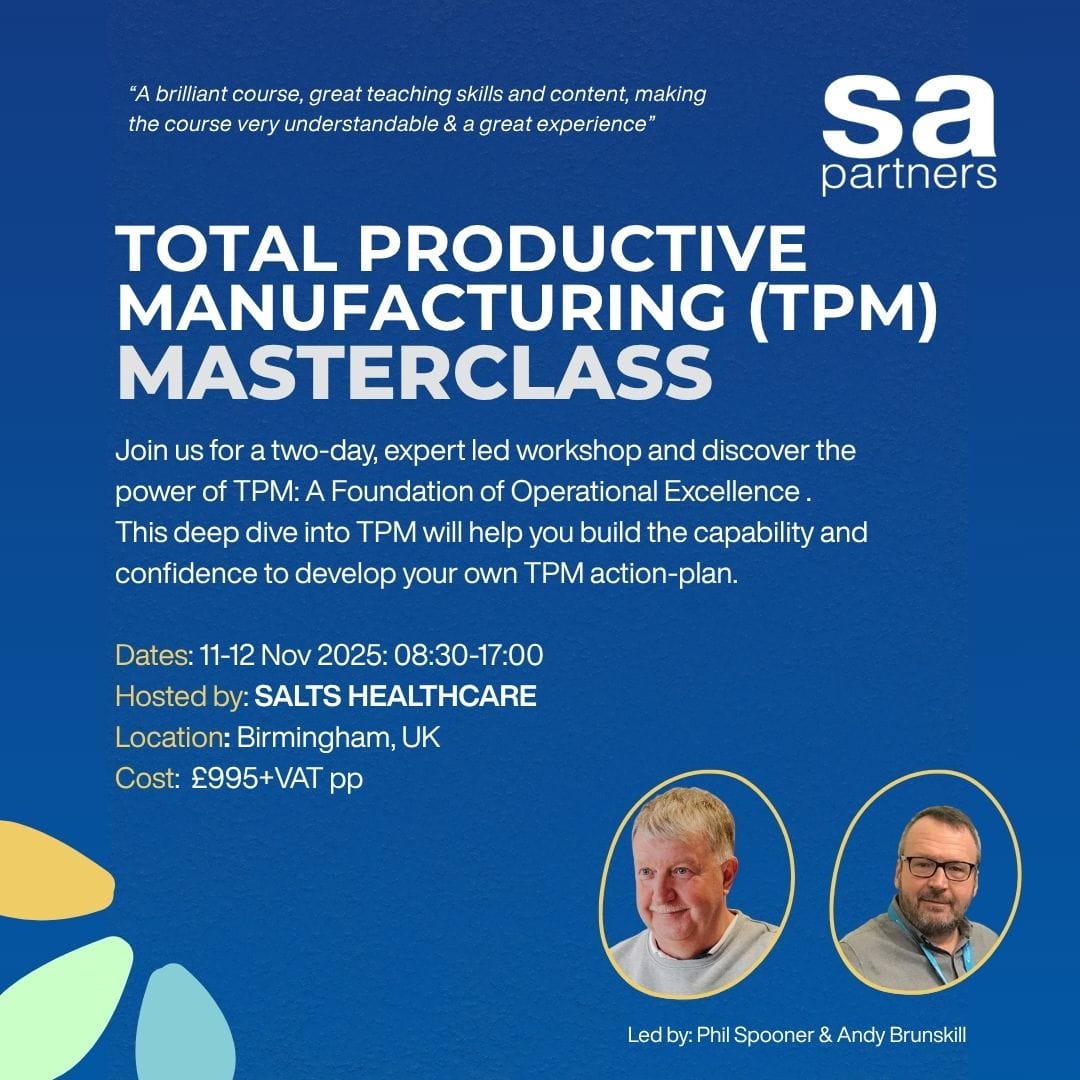

A 2-Day Immersive Experience for Operational Excellence and Manufacturing Leaders

Hosted by Salts Healthcare | Developed by S A Partners

Are you ready to take your asset reliability to the next level?

This exclusive 2-day TPM Masterclass has been designed specifically for Operational Excellence Directors, Manufacturing Leaders, and Asset Management Professionals who want to reduce downtime, improve equipment effectiveness, and embed sustainable reliability practices across their operations.

Rooted in the globally respected Total Productive Maintenance model developed by S A Partners, this hands-on program blends theory with real-world practice. You’ll walk away not just with knowledge, but with a high-level action plan tailored to your own organisation.

Why Attend?

In today’s competitive manufacturing environment, reliability is everything. Equipment failures don’t just stop production – they erode profitability, customer confidence, and employee morale. This masterclass goes beyond tools and techniques to give you a systematic, proven framework for building reliability into the very fabric of your operations.

You’ll learn how to:

-

Maximise asset reliability by embedding TPM principles into daily practice.

-

Align leadership, behaviours, and systems to drive sustainable cultural change.

-

Build capability across teams – from operators to executives – to make TPM part of “how we work.”

-

Apply Lean thinking tools and systems in real manufacturing environments.

-

Transform reactive maintenance into proactive reliability management.

What previous Delegates have said…

“Really great to involve the operations team for some of the steps, I particularly liked ‘stop the rot’ exercise. Great discussion with the trainers & other participants.”

“Very good – great balance of workshop & practical go look see, I generated an enormous amount of ideas and have a great plan to move forward with”

What You’ll Experience Over 2 Days

This is not a lecture – it’s a hands-on, practical masterclass designed to challenge your thinking and sharpen your approach.

Core Modules Include:

-

TPM – theory, practice, and business impact

-

A Day in the Life of an Operator – see TPM through the operator’s eyes

-

TPM Audits & Condition Appraisals – how to identify opportunities for reliability improvements

-

Refurbishment Planning & Asset Management – optimising lifecycle performance

-

Problem Solving in Action – structured approaches that eliminate recurring issues

-

Leadership & Behaviours – the role of leaders in making TPM stick

-

Training & Development for TPM – building skills across the workforce

-

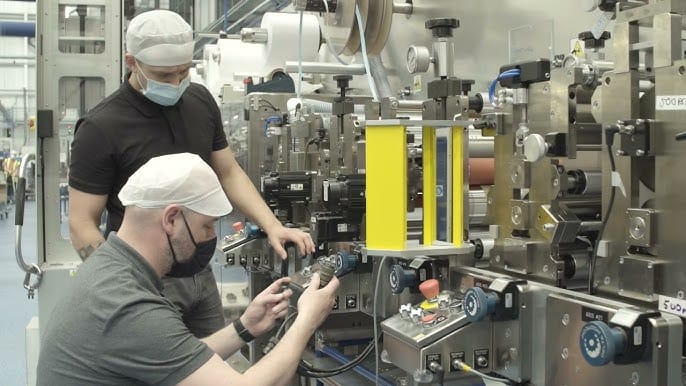

Gemba Walks – test theory on the shop floor and connect learning to practice

Throughout the program, you’ll also participate in a real-life Kaizen activity, applying what you learn in a live environment, with feedback and guidance from expert facilitators.

How It’s Delivered

-

Onsite Training: Two immersive days (2 × 7-hour sessions) hosted at Salts Healthcare, combining case studies, interactive activities, and practical exercises.

-

1:1 Coaching: Every participant will receive personalised coaching from an experienced TPM trainer to support real-world application.

-

Experiential Learning: Practice, apply, and present your own TPM initiative as part of the course accreditation process.

Your Takeaways

By the end of this masterclass, you will:

✔ Understand how to deploy TPM to improve asset reliability and OEE.

✔ Experience the operator’s perspective and learn how to engage them in TPM success.

✔ Build practical skills in auditing, appraisal, and problem-solving.

✔ Strengthen your leadership approach to sustain reliability culture.

✔ Leave with a bespoke high-level TPM action plan ready to deploy in your business.

Who Should Attend?

-

Operational Excellence Directors looking to embed reliability as a core performance driver.

-

Manufacturing Directors & Plant Managers aiming to reduce downtime and boost productivity.

-

Asset & Maintenance Leaders seeking a proven framework to move from reactive to proactive.

-

Change Leaders responsible for embedding sustainable improvement cultures.

Why Now?

Global supply chain pressures and rising production demands mean organisations can no longer afford unplanned downtime. This masterclass will equip you and your leadership team with the framework, tools, and behaviours to build reliability into the DNA of your operations.

About the Host Site

For over 300 years, this family-owned business has been guided by one principle: to put people first. It’s a value that continues to shape everything at Salts Healthcare today. Salts Healthcare is one of the UK’s oldest, family-run companies that has grown to become a highly successful international medical device manufacturer.

Based on the SHINGO Award-Winning Publication

TPM: A Foundation of Operational Excellence

written by: Peter Willmott, Andy Brunskill, John Quirke

Find out more about TPM and the S A Partners 11 Step Model in the following video:

👉 Secure your place today and lead the change towards world-class asset reliability.