Tirlán, formerly known as Glanbia Ireland, is a prominent agribusiness and food company headquartered in Ireland. With a network of over 5,000 farmer suppliers, Tirlan specializes in dairy and grain products, processing over 3 billion litres of milk annually. The company collaborates closely with local farmers to produce and market premium food ingredients and consumer goods and is recognized for its commitment to innovation and sustainability.

Tirlán faced the challenge of enhancing employee engagement and optimizing processes across the organization. The company needed a unified strategy and system to manage performance effectively and identify areas for improvement. This challenge was compounded by the need to align diverse teams across different departments and geographic locations, especially within supply chain and operations.

To address these challenges, we partnered with Tirlán to implement a comprehensive Lean and Continuous Improvement (CI) program. The initiative began with establishing a common purpose and strategy in collaboration with the Executive Leadership team, defining critical success factors and KPIs. A tiered management system, named 3M (Meet, Measure, Manage), was introduced to enhance performance management and engagement. The rollout occurred in phases, starting with manufacturing and operations in 2019, and extended to over 70 teams across the organization by early 2020. Key actions included:

The implementation of the 3M system and the broader Lean and CI approach led to significant improvements in process efficiency and employee engagement. Teams became more aligned with the company's strategic objectives, with clear KPIs, and prioritized projects that drove performance enhancements. The management review process and coaching support embedded a culture of continuous improvement, enabling Tirlán to maintain and build on these gains. The initiative successfully fostered a more cohesive and engaged workforce with a robust framework for ongoing assessment and refinement.

ROI: Pound 1.5 million

Accredited 100 senior leaders in Lean Leadership

Trained over 1,350 Yellow Belts, 116 Green Belts, 23 Black Belts and 5 Master Black Belts

Project deliverables typically yield cost savings of circa £25K, with 5% improvements in other measures

Black belt projects cost savings of circa £100K, with other deliverables increasing by around 10%

Lean Approaches

Tiered Management System

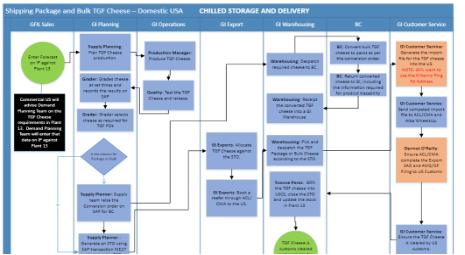

To identify improvement opportunities, we employed Value Stream Mapping, transitioning from using Excel and Visio to the more advanced Process Manager. This dynamic software not only visually maps processes but also manages and controls changes, while integrating all relevant standards and documentation.