Vale Clydach Refinery, located in Clydach, Swansea, Wales, is one of Europe's largest nickel refineries. With over 100 years of history, Vale Clydach Refinery is part of the Vale Group, one of the largest mining companies globally, employing 140,000 people across 37 countries. As one of the oldest nickel refineries in the world, it processes nickel oxide sourced from Canada into high-purity nickel products, which are then shipped worldwide.

To ensure the long-term viability of the site, Vale needed to address several common business challenges, including rising costs, an aging workforce, and outdated equipment. A partnership was established with the site to develop a comprehensive long-term strategic vision and roadmap.

This vision focused on three key areas:

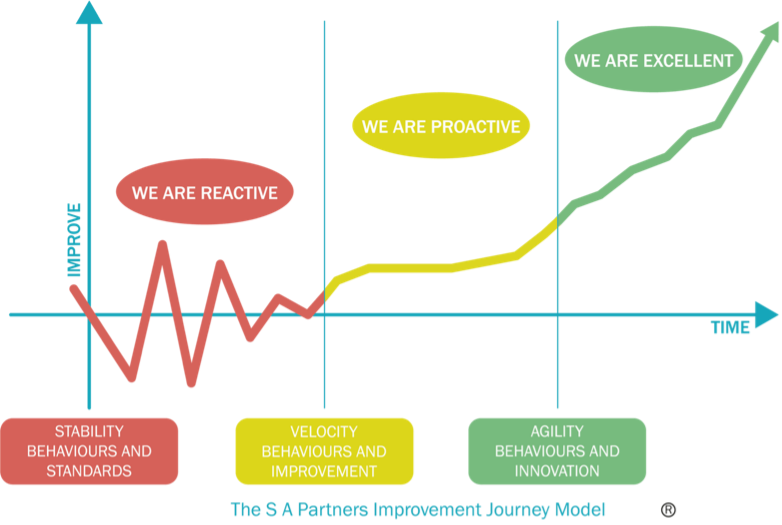

The organization achieved record-breaking productivity following the intervention, exceeding any year in its 100-year history. This success was the result of strong implementation and the active engagement of employees throughout a journey that aligned with everyone’s interests. A long-term vision was developed, and robust systems were built to support it. The focus was not on tools or buzzwords but on mitigating risk and sustaining continuous improvement.

Numerical Results:

Highlights

The key takeaway with Vale was that organizational development requires the involvement of the entire organization. This program wasn’t just about Lean or CI; it was about consistently improving how we work each day and striving for “Excellence in everything we do.”