Marks & Spencer PLC is a major British Multinational retailer based in England, that specializes in selling clothing, beauty products and food products. It is listed on the London Stock Exchange and is a FTSE100 company.

M&S had been working proactively with suppliers on issues of ethical trade, environmental sustainability and lean manufacturing since the launch of Plan A in 2007. Over the years, through their Supplier Exchange programme they have been lucky to capture best practice from experts and suppliers which has helped M&S Food suppliers drive forward positive change in these areas within their businesses. M&S approached S A Partners to support them develop a toolkit for use by their suppliers to support them with their Plan A journey.

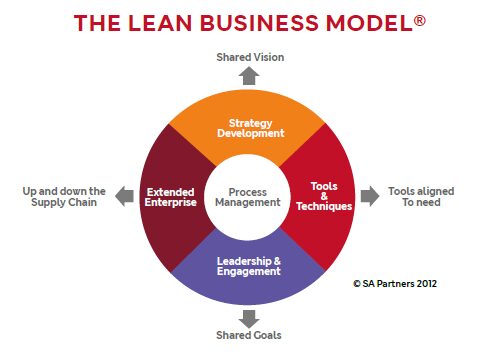

The Toolkit for Plan A was based around the S A Partners Lean Business Model. This model was the product of many years of research on how the best companies deliver profitable growth using Lean Thinking. The toolkit provides a guide to the five elements of the Lean Business Model, which are:

The five elements of the Lean Business Model need to be implemented in a systematic way and frequently this means working on more than one element of the framework at a time. Numerous organisations within the M&S supply chain have used the framework to guide them to create strategies that transform operational and business performance.

Within the toolbox, M&S also promoted the use of the S A Partners Improvement Journey Map fondly known as the 'Squiggly Line' graph. Shown below this shows that most organisations will move through a period of variability and rapid change before they achieve stability and then sustainable improvement.

Further to the Plan A Sustainability Framework S A Partners were asked to develop a benchmarking program to support suppliers on their improvement journey. The program involved evaluation and certification of sites to Bronze, Silver and Gold standards.

The Plan A program at M&S has helped the company make significant improvements to its environmental and social impact:

A number of frameworks were deployed to support M&S with their Plan A program. The Lean Business Model highlighted above provided a framework for individual supply chain companies to implement business improvement programs. S A Partners also worked within the Supply Chain to develop a grading and organisational benchmarking program. This program created a positive re-enforcement and challenge for suppliers to implement improvements, reducing cost and waste in the end-to-end process. As a significant program run over many years, a comprehensive strategy deployment and governance program was also put in place to ensure the organization achieved the results it set out too.